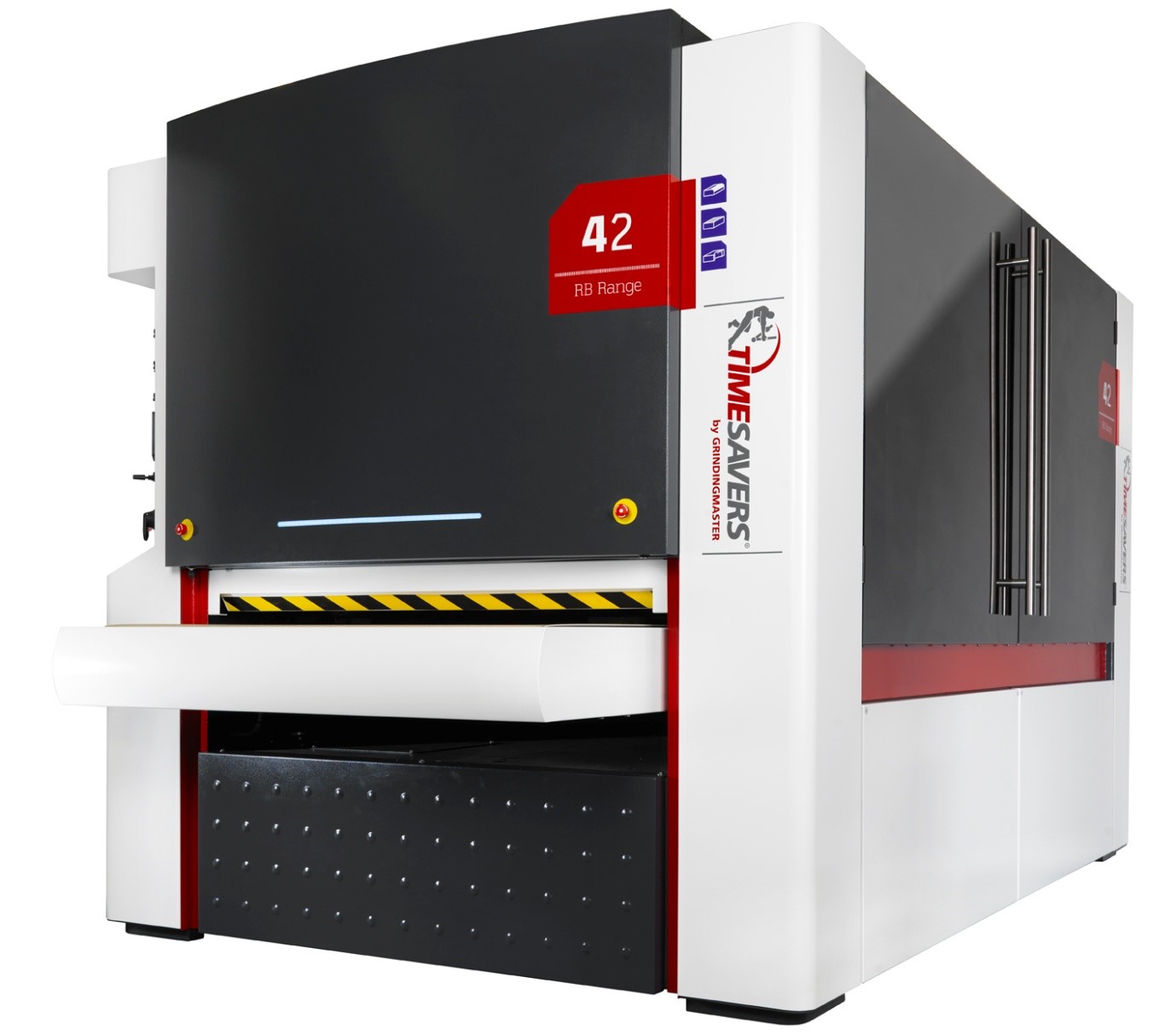

3D and machined parts can be processed because the 42 RB 1350 mm series has frequency- controlled rotating brushes. In addition, small parts (from 30 mm) up to large parts up to 1350 mm can be machined. The materials that can be machined include stainless steel, aluminium, zintec, zinc and laser filmed products.

Standard version:

– Automatic table opening of 0 – 100 mm.

– Carrousel rotating brush head equipped with 4 brushes rotating to the left and 4 to the right.

– Frequency-controlled conveyor belt with a speed ranging from 0.2 to 8 m/min.

– Window panels and lit interior for process observation.

– CE certified.

Applications and benefits:

– Contact time with brushes: 1350 mm.

– The 8 brushes have a total of 46 m2 of abrasive medium.

– The removal of burrs due to laser, plasma, water jet cut and embossed parts in one go.

– Flat, formed and 3D parts with pockets/protrusions.

– Preliminary removal of large burrs and finishing of surfaces.

– Stainless steel, mild steel, aluminium, copper, etc.

– Machining of mixed materials with suitable wet extraction.

– Deburring Zintec, galvanised and plated material.

– Treating small parts (50 x 50 mm) is possible with the standard vacuum table.

– Materials: aluminium, zinc, light metal and plastic without damage including ink-marked parts.

To discuss your requirements please get in touch on 01553 764120 or email sales@optima.co.uk